Business content

Ingot・Scrap (Primary Ingot、Secondary Ingot、Scrap)

We trade the scraps, the ingots and the processed materials of nonferrous metals.

We can satisfy the various requests of customers from our connection with worldwide suppliers.

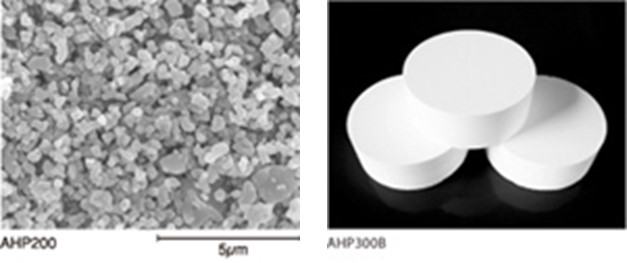

High Purity Alumina

Characteristics

This is an alumina powder with extremely high purity by maximizing the degree of purification.

AHP200 is a grade with submicron particles and has excellent sinterability.

AHP300 is a grade with a higher degree of purification and suitable for optical materials.

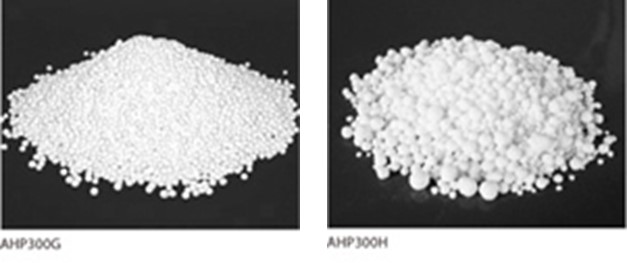

AHP300G is a grade with spherical particles and has increased flowability.

AHP300H is a grade with high packing density particles that allow high filling in a crucible.

AHP300B is a grade with pellet-like particles that allow higher filling in a crucible.

AHP300B in combination with AHP300G/H can maximize sapphire output.

Recommended Applications

Magnetic recording media

Monocrystal (sapphire etc.)

Translucent ceramics

Fluorescent materials

Thermal spray materials

Ceramics

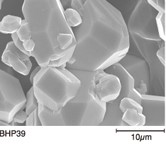

High Purity Aluminum Hydroxide

Characteristics

More than 99.9% purity of AI(OH)3 is achieved in this product eliminating impurities,such as Fe, Si, and Ca to the practical limit. Particle size can be controlled upon request

Recommended Applications

Raw material for high purity industrial chemicals

Additive for optical glass

Additive for battery materials

Raw material for high purity alumina

High Functional Aluminum Alloy Sheet Products used in Diversified Industrial Sectors

We offers high quality aluminum alloy sheets that meet customers' applications and provides attentive services worldwide, and develops advanced products anticipating the future.

Aluminum Alloy Plates and Sheets - Standard Product Range

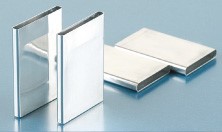

Aluminum Alloy Sheets for Lithium-ion Battery Cases (LB Series)

Characteristics

This is an aluminum alloy specially developed for lithium-ion battery cases.

The material has superior creep characteristic and swelling of the battery case can be effectively prevented

due to charging for long time and discharging at high temperature, as well as use under normal temperature.

The material has high mechanical strength and excellent laser weldability.

Deep drawing into various shapes like cylinder, rectangular solid, etc. is possible.

Applications

Electrical and electronics - Lithium-ion battery cases,deep drawn parts to which high mechanical strength is required,enclosures, parts, etc. to which laser beam welding is applied.

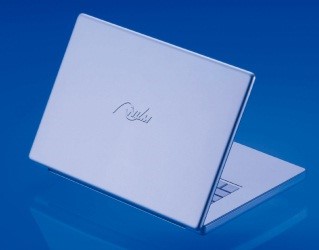

High Quality Anodized Aluminum Alloy Sheets (A Series)

The material is suitable for small lot production, such as prototyping and development work, or for production with a limited lead time.

Characteristics

Linear marks after anodizing treatment reduces, which leads to significant increases in the yield.

The material has a fine surface quality for stable color tone without a yellowish tint.

Smut produced by alkali etching and chemical polishing is reduced.

* Smut: Substances produced in the etching process insoluble to water.

Applications

Electrical and electronics - Enclosure case for digital cameras,laptop PCs, cell phones, etc., products to which requirements on the design and decoration are high.

High Strength and High Formability Aluminum Alloy Sheets (N532)

Characteristics

The material is high functional 6000 series aluminum alloy oriented for formability and anodizability.

6000 series alloy has higher strength compared to 5000 series aluminum and also has excellent electrical conductivity and heat dissipation.

MX61 grade with significantly improved formability is also available for use in specific applications.

Products are available for thickness of 0.4-2.0 mm.

Applications

Automotive and transportation - High strength parts like oil pans, under guards, etc.

Electrical and electronics - Enclosures, panels for electronic devices, etc.

Other - Replacements from cold rolled steel parts

6000 Series Sheet for Enclosure

Characteristics

The material is high functional 6000 series aluminum alloy oriented for formability and anodizability.

6000 series alloy has higher strength compared to 5000 series aluminum and also has excellent electrical conductivity and heat dissipation.

MX61 grade with significantly improved formability is also available for use in specific applications.

Products are available for thickness of 0.4-2.0 mm.

Applications

Electrical and electronics - Parts for electronic equipment, enclosures for digital cameras and cell phones, precision parts that require strength and heat dissipation.

High Formability Aluminum Alloy Sheet(AFX2、MFX2)

Characteristics

The material shows total elongation of 40% and local elongation of 10% or more and even with wrinkling, the material elongates further without the work hardening.

The material has excellent formability in bulging. (Eriksen Value 10.5 or above)

The material has excellent heat dissipation. (Electrical conductivity of 50% IACS or above)

Applications

Automotive and transportation - Fuel tank protectors difficult to form, insulator parts, stamped parts in complex shapes, etc.

Electrical and electronics - Lighting cover, panels for electronic devices, etc.

Other - Replacements from cold rolled steel parts

Aluminum Extrusion・Aluminum Rod

The extrusion of aluminum process can form products of prescribed shapes by pressurizing a billet to extrude it through the die.

It uses for the building, vehicle, electricity and decoration.

Recently, it is increase to use the aluminum extrusion for OA apparatus and the precision instrument.

Prefabricated refrigerator and freezer panels

Asia has become a central player as well as a major consumer in the global food distribution industry and bases from which to provide quick accommodation for this in necessary.

Panel system refrigerators and freezers play an essential role in the estabishment of strategic facilities for this.

We have earned a high requtation for our flexible design, quick delivery, and reliable construction.

Aluminum wire

Aluminum wire produced by Nikkei Sangyo base on Nippon Light Metal technology is used in the field of electrical cables, electrical and electronics parts, and machines.

And these products are widely adopted as aluminum wire rod for forging materials in the field of car, bicycle, electrical device etc and welding wires in the field of ship etc.

The followings are certified.

JIS Z 3232

Nippon Kaiji Kyokai (NK)

Lloyd's Register (Lloyd's)

Det Norske Veritas (NV)

American Bureau of Shipping (ABS)

Deutsche Bahn AG (DB)