Technologies

Home ⁄ Technologies ⁄ Joining (FSW)

Joining (FSW)

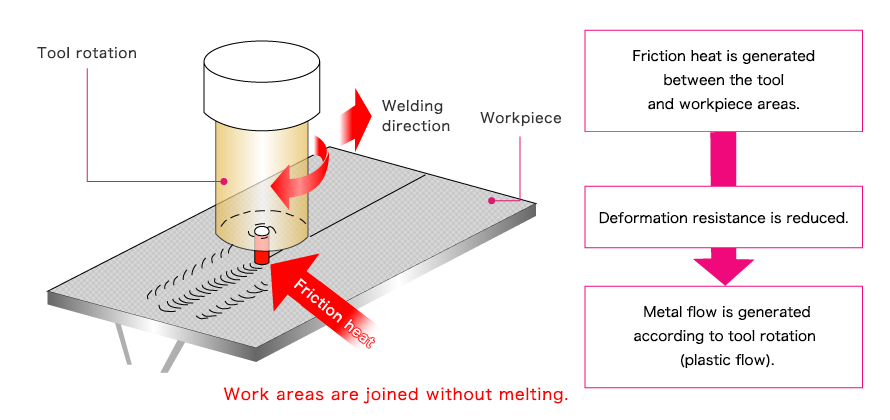

FSW (friction stir welding) is a new solid phase bonding method suitable for joining aluminium.

A tool with a tip that rotates like a drill (the probe) is pressed firmly against the weld location of the aluminium alloy. The resulting frictional heat is used to soften the weld location and stir the metal on both sides of the weld location.

The softened aluminium alloy reaches a clay-like state.

After passing through the tool, the weld location cools and returns to its solid state. The join is now complete. This process results in more aesthetically pleasing weld surfaces.

What is friction stir welding (FSW)?

F: Friction

S: Stir

W: Welding

S: Stir

W: Welding

Mechanism behind FSW

- Technologies of Nikkeikin ACT

- Basic Data on Aluminium

- Manufacturing Process of Extruded Aluminium Shapes

- How Aluminium Alloys Are Selected

- Technologies of Nikkeikin ACT

- Alloys

- Coatings (Color Management)

- Extrusion (Difficult Shapes and Ultra-Precision)

- Joining (FSW)

- Processing (Welding)

- Processing (Brazing)

- Processing (DI Processing)

- Latest Development Case Examples

- Developing Alternative Structural Component Businesses

- Butterfly Windmill Development