Technologies

Home ⁄ Technologies ⁄ Processing (Brazing)

Processing (Brazing)

Nikkeikin ACT manufactures the single largest brazing honeycomb panel in Japan.

Brazing honeycomb has the following features:

- (1) Resistant to deterioration (recyclable)

- (2) Lightweight and highly rigid (good workability)

- (3) Also supports curved designs

- (4) Also supports the requirements of large panels

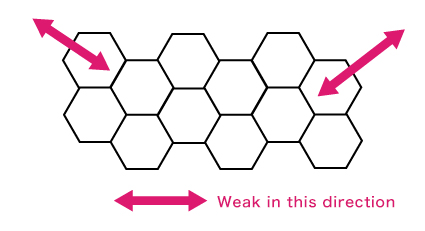

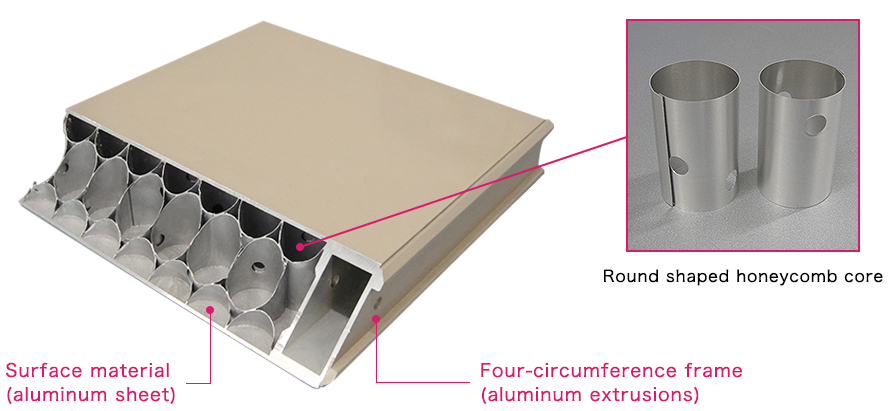

In terms of structural features, brazing honeycomb adopts a round (round-core) honeycomb shape instead of the usual hexagonal beehive shape. Thanks to this round-core honeycomb shape, brazing honeycomb offers the following features:

- (1) Ability to manufacture various shapes such as triangles

- (2) Support for bend processing, notch processing, and more (For bends, the upper and lower radii are different, causing a round core to become trapezoid.)

- (3) Strength in all directions

Features:

Use of round-core honeycomb

- Technologies of Nikkeikin ACT

- Basic Data on Aluminium

- Manufacturing Process of Extruded Aluminium Shapes

- How Aluminium Alloys Are Selected

- Technologies of Nikkeikin ACT

- Alloys

- Coatings (Color Management)

- Extrusion (Difficult Shapes and Ultra-Precision)

- Joining (FSW)

- Processing (Welding)

- Processing (Brazing)

- Processing (DI Processing)

- Latest Development Case Examples

- Developing Alternative Structural Component Businesses

- Butterfly Windmill Development