Technologies

Home ⁄ Technologies ⁄ Processing (Welding)

Processing (Welding)

Nikkeikin ACT also supports the welding of large parts. Generally, TIG welding and MIG welding are used.

When welding aluminium, we are especially careful of the following:

- (1) Working in an inert gas atmosphere to prevent oxidation of melted parts

- (2) Using high heat input to achieve high latent heat and thermal conduction

- (3) Removing oxide film from material surfaces

- (4) Taking into account welding distortions due to a high linear expansion coefficient

- (5) Minimizing loss of strength in the base material due to the effects of heat

We also determine the optimal welding conditions when performing each type of weld.

Aluminium welding

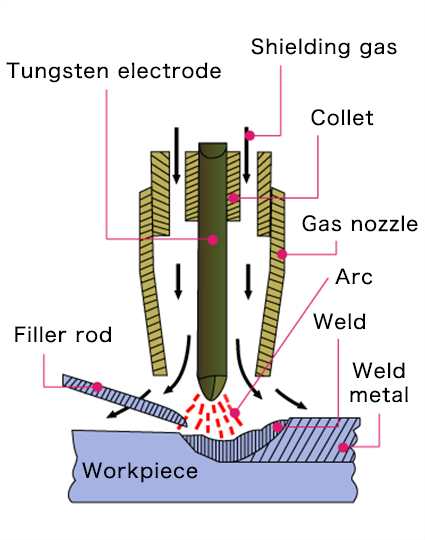

Principles of TIG welding

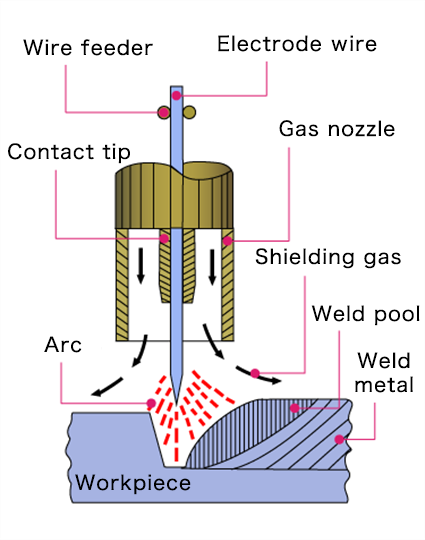

Principles of MIG welding

Features and notes:

- - To prevent oxidation of melted parts, welding must be performed in an inert gas atmosphere.

- - High heat input is required because the melting point is low, but latent heat and thermal conduction are high.

- - Oxide film must be removed from material surfaces.

- - Be careful of welding distortions due to the high linear expansion coefficient.

- - The base material is susceptible to loss of strength due to the effects of heat during welding.

- Technologies of Nikkeikin ACT

- Basic Data on Aluminium

- Manufacturing Process of Extruded Aluminium Shapes

- How Aluminium Alloys Are Selected

- Technologies of Nikkeikin ACT

- Alloys

- Coatings (Color Management)

- Extrusion (Difficult Shapes and Ultra-Precision)

- Joining (FSW)

- Processing (Welding)

- Processing (Brazing)

- Processing (DI Processing)

- Latest Development Case Examples

- Developing Alternative Structural Component Businesses

- Butterfly Windmill Development