MESSAGE

MENU

OUTLINE & HISTORY

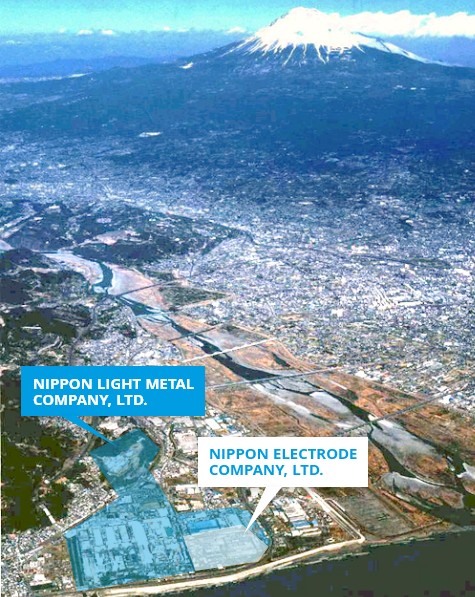

Our company was established in May 1945 to supply Cathode Carbon blocks for Aluminum Reduction Pots to Nippon Light Metal Co., Ltd.

Since then, we have top-level evaluation in the world by manufacturing and selling Carbon products not only for Cathode Carbon blocks for Aluminum Reduction Pots but also for large Carbon blocks used in Blast Furnaces and Electric Furnaces.

From the start of operation, our technical team has been continuing research efforts, and efficiency of the Aluminum Reduction Pot has been improved and the campaign life has been greatly extended by our high quality Carbon products.

In addition, Carbon blocks for Blast Furnaces and Electric Furnaces are manufactured using new technology developed with Nippon Steel, and have the world's highest quality. We have been greatly contributing to the development of the Japanese steel industry.

Also we manufacture and sell Carbon specialties products such as Carbon paste for electrodes, general Graphite materials, and Electrolytic plates, which were developed by using best characteristics of Carbon.

Corresponding to our customer’s request, we are engaged in Heat treatment business using Carbon manufacturing equipment. In recent years, we have also been focusing on the graphitization Heat treatment business for carbon used as a raw material for negative electrode materials for lithium-ion batteries with our proprietary vertical continuous graphitization equipment.

OUTLINE

Nippon Light Metal Co., Ltd. 51%

Mitsubishi Corporation 29%

SEC CARBON, LIMITED 20%

President : Hideaki Suginaka

Executive Director : Hiroyuki Okada

Executive Director : Yukihiro Sugiyama

Executive Officer : Yoshiki Naito

Executive Officer : Shuji Kawarazaki

Executive Officer : Takayuki Yatsu

5600 Kambara, Shimizu-ku, Shizuoka-shi, Shizuoka Pref. 421-3203

Telephone:+81-54-385-3141

Facsimile:+81-54-388-2872

- ① Cathode Carbon, Sidewall Carbon and Carbon paste for Aluminum Reduction Pots

- ② Carbon blocks, Carbon paste and Carbon cement for Blast Furnaces

- ③ Carbon specialties products : Carbon troughs, tapping Carbon, Carbon bricks, Carbon raisers, Carbon paste for Soderberg-type electrodes.

- ④ Heat Treatment Business

Asia

China, South Korea, India, Taiwan, Indonesia, Vietnam

Oceania

Australia, New Zealand

Europe

Russia, Germany, Sweden, Italy, Netherlands, Spain

North America

United States of America, Canada,

South America

Brazil, Chile

Africa

South Africa, Mozambique

NDK MANAGEMENT POLICY

Corporate Philosophy

Contribute to improving people’s quality of life and environmental protection by

continuing to create business, focused on Carbon products.

Basic Policies

- NDK will create rewarding, safe and healthy workplaces.

- NDK will continue to provide diverse value to world wide customers by deepening the

level of collaboration and coordination within and outside NLM Group. - NDK will respect limited natural resources & energy to achieve carbon neutrality, and contribute to development of sustainable society.

- NDK will engage in fair and honest business operations, with respect for human rights, diverse values and compliance with laws, social norms.

- NDK will continue to create businesses by always training, challenging and growing to become a global human resources group.

HISTORY

Developed Carbon Block (BC-5) for blast furnace and supplied to Yawata Steel Works for the first time.

No.1 Ried-Hammer Furnace started operation.

Super Micropore Carbon Block (BC-8SR) was launched.