Products

Welded Products (Air Tanks)

We have successfully produced tanks that are significantly lighter than existing iron and stainless steel products. We have also enhanced our tanks' resistance to corrosion. Tanks can be built using the optimal structure and provided at the optimal cost.

ACT's welding techniques and design capabilities

| Tank capacity | 15 L to 190 L (max) |

|---|---|

| Tank length | 410 mm to approx. 2000 mm (max) |

| Sheet thickness | 3.0 mm to 6.0 mm (sheet thicknesses permitted for automatic welding: 3.0 mm to 12 mm) |

| Tanks that use difficult shapes | Two-compartment tanks and thin-walled tanks |

We can propose shapes (wall thickness and dimensions) designed for stable quality. Because we are JBA-certified for MIG and TIG automatic welding (we have passed the welding test, visual inspection of front and back beads, tension test, and bend test), we can offer improved product accuracy and achieve more aesthetically pleasing exteriors.

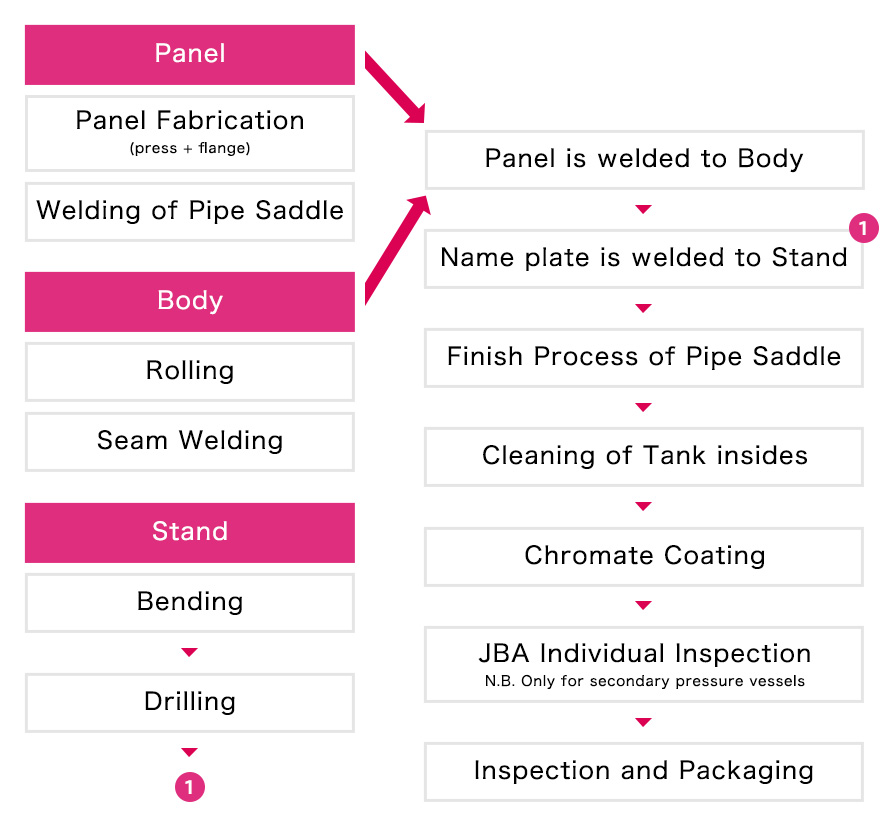

Flowchart

With our comprehensive production management and quality assurance system, we will provide safe, secure, and high-quality products.

- Railways

- Long Materials for Train Cars

- FSW Products (Cart Covers)

- Interior Material Units

- Welded Products (Frontpieces)

- Welded Products (Air Tanks)

- Large Heat Sinks

- Trucks

- Industrial Equipment

- Machinery / Communications / Electronics

- Social and Civil Infrastructure

- Food and Lifestyle Products

- Natural Energy

- Damping Materials for Construction

- Neutron-Absorbing Materials